Economize Fuel

![]()

![]() BUY ONLINE NOW! VISIT OUR WEBSTORE!

BUY ONLINE NOW! VISIT OUR WEBSTORE!

![]()

![]()

Portable Generators | Standby Generators | Air Compressors | UPS Uninterruptible Power Sources | Automotive Parts

DIESEL ACTIVATOR KA3 - PRODUCT INFORMATION

This information page will give you detailed knowledge about our product, how it works and how it will save

you money while reducing emissions. After reading it, you can make an educated decision to buy our product.

|

|

|

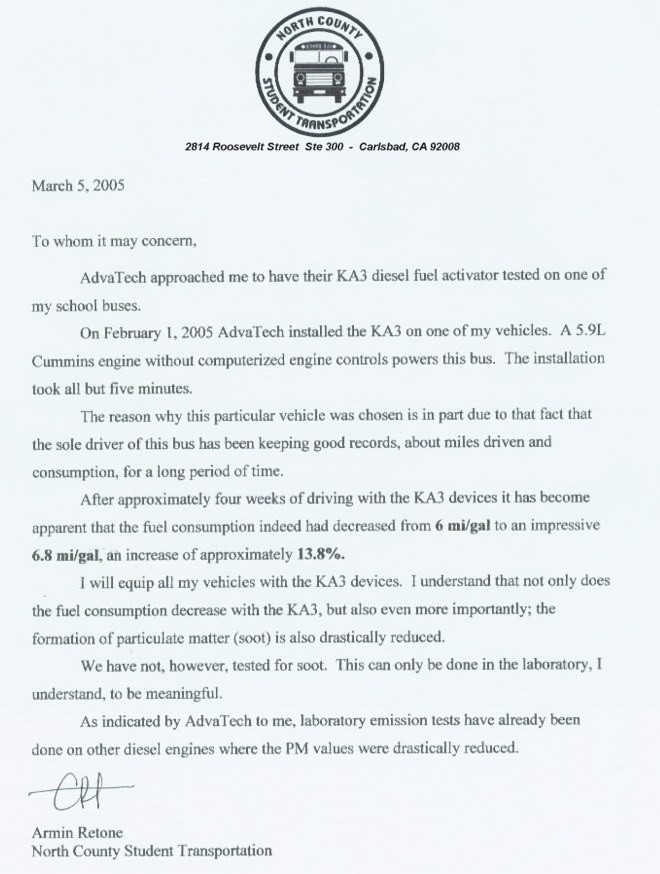

Our Fuel-Activators KA2 and KA3 are designed in accordance to laws of physics (Lorentz Force Law). The Activator Units are invented, designed, and manufactured in Germany. They are successfully street-tested, and have been on the German market for over 4 years. The use of the strongest magnetic material currently attainable will guarantee you satisfying results, and service for life.

Patented in Europe and in the USA

While the Type KA2 activator has been used for its positive physical effects on gasoline-engine fuels for years by applying it to the fuel feed line, another new device has now also been successfully employed directly at the injectors in diesel engines.

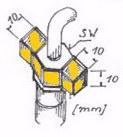

The new Fuel-Activator KA3 is positioned on each injector directly on the injector cap nut. Owing to its flexible construction, it can be clamped on without additional fastening devices. In accordance with the design principle (as in KA2), the magnetic fields that are effective across the injectors cover the area from the injection nozzle to the cylinder head, so that the fuel that is under injection pressure is already influenced, i.e., fully concentrated, during atomization (Lorentz force). With diesel oil, the optimization of the combustion process is of decisive importance for the consumption, and the emission of particulate matter

-soot- and other particles that have to be held back by suitable filters. Nonfilterable harmful gases, such as the carcinogenic substance benzopyrene, will be be reduced by the improved combustion process in the cylinder.

IGNITION QUALITY or VALUE

When fuel is injected into the combustion chamber of a diesel engine, ignition does not occur immediately. The interval between the commencement of fuel injection and the commencement of combustion is known as the " ignition delay" and is a measure of the ignition quality of the fuel. This delay period depends on the nature of the fuel, the engine design, and on the operating conditions. If the delay is too long, the engine may be hard to start and when the accumulated fuel does ignite, the rate of pressure rise may be so great that it causes roughness or diesel knock. The effects of diesel knock are similar to the effects of knocking in gasoline engines, causing loss of efficiency and power output and a possibility of mechanical damage to the engine if the knocking is prolonged.

Magnetic treatment of the diesel fuel prior to atomization results in better ignition values, which is equivalent to an increase in the cetane number ( or you could say it more practical: It is the same if you had a better quality of fuel), We reduce the fuel's flash-point from before at 183.2°F (84°C),

down to 134.6°F (57°C), after treatment with KA3, which also leads to better cold-start behavior.

The so called "Diesel-knock" resedes, the engine runs smother than without our unit KA3.

Vienna's, Univerity of Technology laboratory tests showed the following: Vienna's, Univerity of Technology laboratory tests showed the following: Normal flashpoint of Diesel Fuel is at 183.2°F (84°C)

KA3 treated Diesel fuel has a reduced flash point of 134.6°F (57°C).

This explains (i) the better cold-start behavior of Diesel engines with installed Unit KA3, and (ii) the more efficient combustion, what leads to reduced consumption and emissions.

The result is a noticeable improvement in the running of the engine, less soot - particulate matter- formation and lower fuel consumption. This reduces stress on the soot filters and also protects the environment. The reduction in consumption is up to max.17%. As with the KA2 (gasoline)

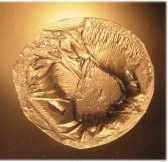

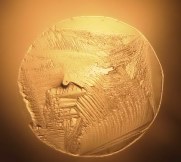

Microscope (x800) photo of an Diesel-Oil-drop

Picture 1 Picture 2

Untreated Oil drop Oildrop KA3 charged

Flashpoint 183.2°F (84°C) Flashpoint 134.6°F (57°C)

Another evidence of the effectiveness of our Fuel Activator KA3, pointing to it's ability to influence the

bipolar hydrocarbon molecules in the fuel. Through the electrostatic charge, these groups (clusters) are braking up and allow a more sufficient combustion process. You can see the difference in the drop's

surface.

The untraeted oil-drop -Pic 1- shows us through it's rough surface that the bipolar hydrocarbon molecule clusters are dominating the fuels inner structure.

Now treated -Pic 2- we can observe a smooth surface. Evidence that these clusters are broken up.

Therefore, the affinity to oxygen is improved. The fuel's flashpoint is lowered, a most efficient

combustion can take place, where fuel is burned more efficiently, power is enhanced, soot formation is lowered, and a reduction in fuel consumption is reached.

This device has an unlimited life-time.

The Activator KA3 is very easy and quick to install. There is no limitation on its

effectiveness depending on the power of the particular engine. It can be employed

up to a maximum temperature of 170°C (338° F).

The installation position is unmistakable. The Units are heat- and corrosion-resistant,

therefore usable on all engines, also on Marine Diesel engines.

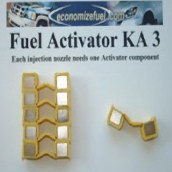

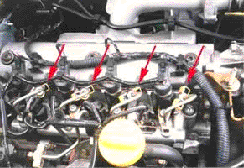

Installation Instructions - Activator for Diesel Engines KA3

KA 3 Diesel Fuel-Activators are easy to install (Easy Do It Yourself in minutes).

Each injection line need one Fuel-Activator. (6-Cylinder need 6 / 8-Cyl. need 8 etc.).

The KA3 will be placed directly on top of the injector cap nut of each injector.

Due to the elastic design you can clamp it on easily without using any tools.

No additional fastener necessary.

The KA3 design will make it impossible to install the KA3 the wrong way.

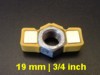

The KA3 fits on all types of diesel engines with a cap nut size of 14mm to 19mm

(wrench size) (0.551 to 0.748 inch - or - 9/16 inch to just over 3/4 inch).

Regards ONLY propulsion engines: KA3 can be installed up to 24mm cap-nut size [60º angle].

Over 24mm diameter, each cap nut needs 2 Units, addressing the higher fuel flow volume.

Order for 6 Cylinder $324 + 10,50 S&H

|

||

|

||